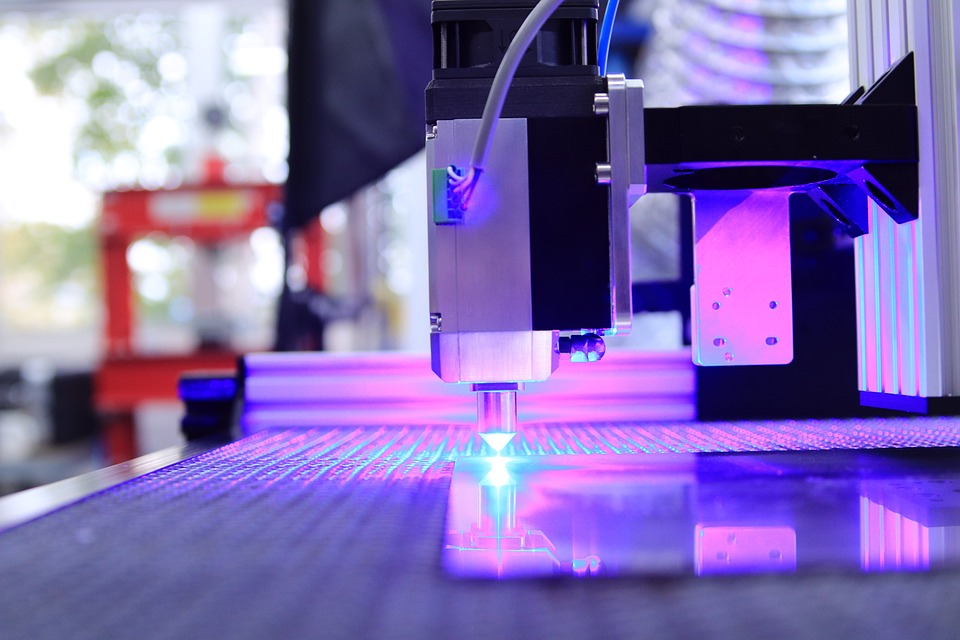

In the world of manufacturing, CNC machining has become one of the most widely used manufacturing techniques. It offers a high level of precision and efficiency, making it an essential process for areas such as aerospace, automotive, and medical industries. Due to its accuracy and speed, CNC machining creates intricate and precise parts that can be difficult to make using traditional methods.

CNC Machining, or Computer Numerical Control Machining, is a manufacturing process that uses computer programs to control machinery to produce parts. The process moves in three dimensions and can work on various materials such as metal, plastic, and wood. This manufacturing process offers many benefits, including speed, accuracy, and flexibility. Unlike traditional machining, CNC Machining can produce a large volume of parts in a short amount of time with minimal errors.

The flexibility of CNC machining is also an advantage. With programmable computers, multiple parts can be produced with ease by simulating a virtual environment before production begins. This process allows manufacturers to make design changes quickly, and the results are produced almost instantaneously.

CNC machining is becoming increasingly popular due to its speed, accuracy, and flexibility. This method can produce intricate and precise parts that would be challenging to make using traditional methods, making it an essential process for the manufacturing industry.