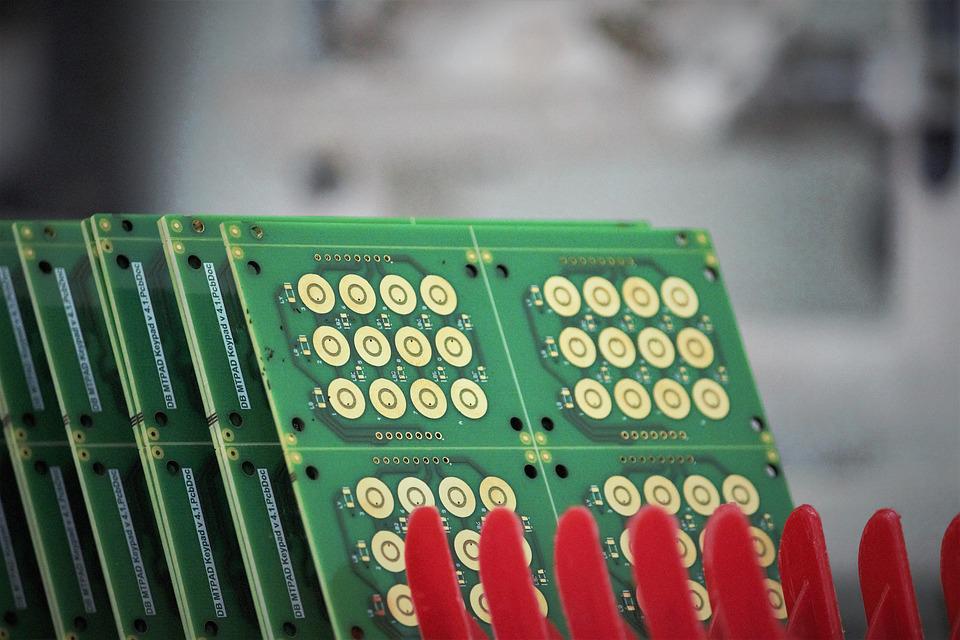

Multi-layer PCB is a type of Printed Circuit Board that has more than one layer of copper foil. This design allows for more complex circuitry and is often used in high-end electronics. PCBs are also more difficult and expensive to produce, so they are not commonly found in consumer electronics.

What should I know about this?

Multi-layer PCBs can have four, six, or eight layers. The more layers there are, the more complex the circuitry that can be achieved.

To make a Multi-layer, first, a substrate is needed. This is typically made of FR-42 material, which is a type of glass-reinforced epoxy laminate. Next, copper foil is bonded to both sides of the substrate. This is done by applying pressure and heat to adhere the foil to the substrate. Then, the desired circuitry pattern is etched into the copper foil using a photoengraving process. After that, a dielectric layer is applied to both sides of the substrate. This layer insulates the copper traces and prevents them from shorting out. Finally, the outer layers of copper are applied and the entire stack is bonded together under pressure and heat.

We hope this information has been useful to you.